TL;DR: Sonin Create is where we regularly put our time and resources into experimenting with the very latest tech. In the past, we’ve looked at how iBeacons, chatbots, AI and AR can help expanding businesses to grow better. But this Christmas, we were approached to run a discovery workshop for the leading brand in manufacturing, transport and logistics: Santa’s Workshop.

CEO and Founder of Santa’s Workshop, Santa Claus, approached Sonin with a brief. After enjoying years of consistent growth, the workshop was struggling to meet an always-increasing number of letters. And the exponential number of presents needed to meet demand. At the same time, concerned parents and press publications were pressing for the operation to be more eco-friendly.

The stakes were high. Santa needed to save Christmas by streamlining production and distribution. But the solution had to support everyone involved with a 100% success rate. Nothing could endanger the chance of kids receiving their presents come Christmas Eve.

The Set-Up

Santa needed a solution – and fast. So we invited him and the key stakeholders involved in the production and distribution process into Sonin HQ for a discovery workshop.

The goals for the day included:

- Build a foundation knowledge of the business behind Santa’s Workshop

- Understand the entire wishlist fulfilment process from start to finish

- Identify all the key challenges, the limitations and the positive experiences throughout

- Pinpoint the biggest opportunities and prioritise them by business value, risk and speed.

Attending from Santa’s Workshop was:

- Santa Claus – Founder, CEO & Sleigh Operator

- Shinny Upatree – Head of Customer Experience

- Alabaster Snowball – Head of Present Manufacturing & Quality Assurance

- Wunorse Openslae – Head of Logistics & Supply Chain

From Sonin, we had:

- Sophie Parsons – Project Manager

- Sarah Preston – Senior Designer

- Tim Moore – Account Director

- Paul Jarrett – Managing Director

Also in the room:

- 3 whiteboards

- 282,109 post-it notes

User Personas

First off, we needed to establish the key people involved in the process. Each with their own unique set of requirements. Whatever solution we came up with would have to serve every persona in some way.

Children

“When I’m writing a letter to Santa, I want to know what I need to include so I can make sure I get every present and wish I’ve asked for.”

Unclear Address

Thanks to all the fake addresses found on the internet, it’s difficult for children to know where to address their letters to.

No Feedback

With no feedback from Santa’s Workshop, children are often left wondering whether their letter has even arrived or whether they’re even on the nice list.

Santa Claus – CEO & Founder

“When I’m rushing to meet my Christmas Eve delivery quota, I want to know I’m being efficient as possible so I can fulfil my mission of bringing joy to the world.”

Limited Visibility

With all my different departments disconnected, it’s hard to know whether we’re on track until I get my delivery schedule on Christmas Eve.

Alcohol Consumption

Even though my metabolic make-up lets me process huge quantities of alcohol, I still worry about how sharp I am at the sleigh.

Shiny Upatree – Head of Customer Service

“When I’m overseeing all the letters we receive, I want to be able to process and cross-reference them quickly so I can make sure every child has their wish granted.”

Hard to Read

Many of the letters have hard-to-read handwriting or are in a non-standard format which increases the time-to-process.

Irregular

Not having a standard format across all incoming letters means it takes ages to manually process requests.

Missing Information

Letters with missing information such as names and addresses are in danger of missing their

Alabaster Snowball – Head of Manufacturing & Quality Assurance

“When we’re in the last-minute crunch, I want to know exactly how many presents we still need to produce so I can fulfil every request.”

Manual Work Orders

Writing and distributing work orders to various departments in Santa’s Workshop isn’t efficient. It’s just the way we’ve always done it.

No Visibility

I have to rely on manual reports to check our progress on toy production. This means that in the last-minute crunch, I’m often left unsure if we’ll meet our targets.

Wunorse Openslae – Head of Logistics & Supply Chain

“When we wite a distribution plan for Santa, I want the flexibility to adapt it so we can ensure every delivery gets made.”

No Flexibility

Every year, we have to manually write a distribution plan and hand it over to Santa. It’s then incredibly impossible to update this to account for changes in the schedule or weather conditions.

Carbon Footprint

I’m coming under increasing scrutiny about the carbon footprint of our operations. I need to prove we’re making progress on this front towards a completely carbon neutral process.

The Last Mile

The last mile makes up 28% of my costs. It’s the most inefficient part of our process and it’s where things are most likely to go wrong.

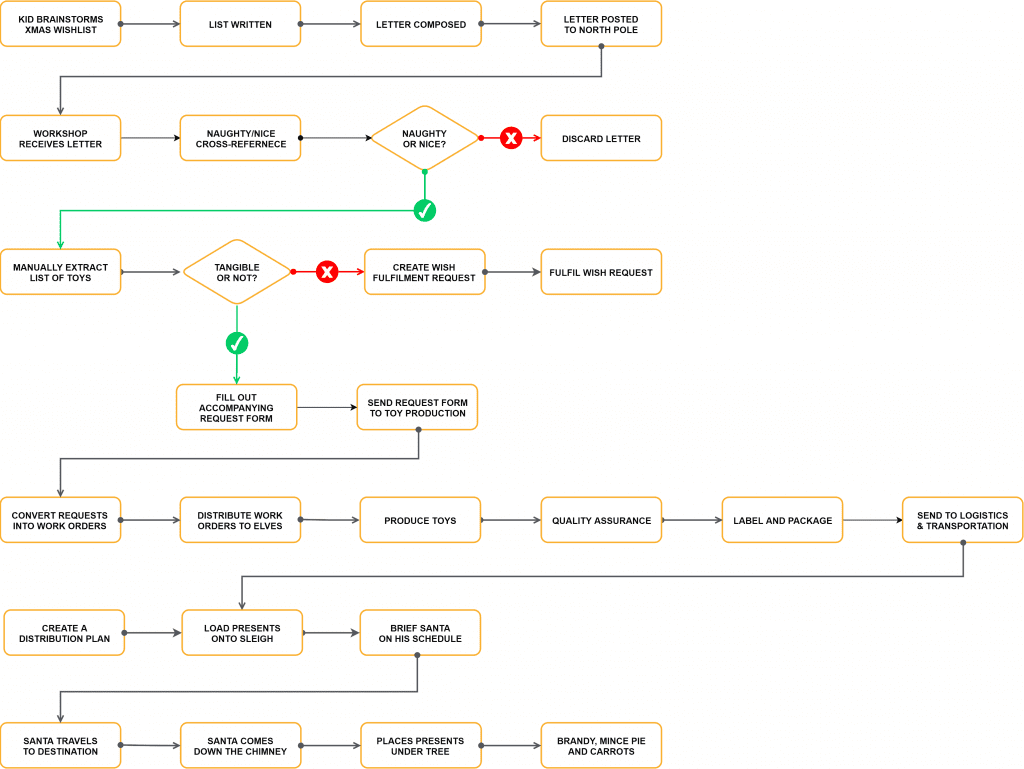

Santa’s Process – Start to Finish

Next, we mapped out Santa’s process from start to finish. All the way from when kids brainstorm their Christmas wishlists to when Santa tucks into his mince pies and brandy.

By doing this, we pinpointed four key stages to focus on:

- Submitting Lists

- Request Processing

- Toy Production

- Present Delivery

Santa’s Workshop Current Process

For each stage, we then worked together to pinpoint four aspects:

- The actions people are taking along the way.

- The questions people ask when they’re trying to do something.

- The delightful moments where great experiences make each person happy.

- The pain points where bad experiences are causing friction and frustration.

Submitting Lists

At the beginning of December every year, just over 526,000,000 kids put pen to paper and list out their most-wished-for presents. But with a vague postal address and no standard format to follow, there’s a huge opportunity to streamline this process.

Request Processing

Every year, Santa’s Workshop has a half-a-billion long naughty and nice list which, of course, must be checked twice. This then has to be cross-referenced with the huge number of letters for Santa and his team to process and cross-reference.

Production

The average letter to Santa contains a staggering 16 presents. Let’s look at the maximum liability for Santa’s Workshop on any given year. In a worst-case scenario, where every kid ends up on the nice list, there are 8,416,000,000 presents to build before Christmas Eve.

Distribution

There are over half a billion deliveries to be made on Christmas Eve. That’s 22 million kids an hour, 365,00 kids a minute or 6,100 a second. It’s a transport and logistics nightmare that becomes increasingly difficult every year that goes by.

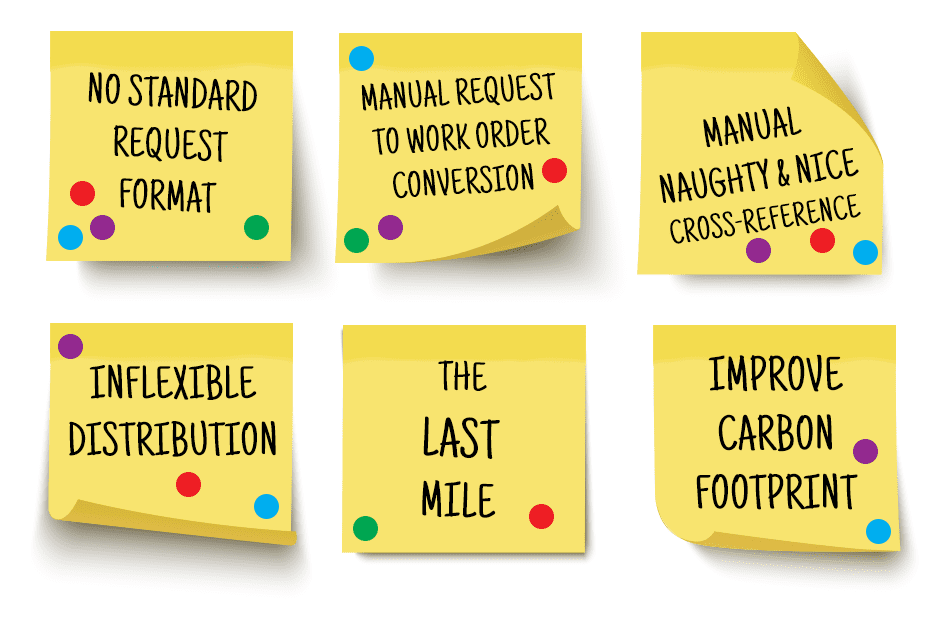

Prioritised Painpoints

After breaking down each part of the process, we had a combined list of every single pain point in the Santa’s Workshop process. So out came the sticky coloured dots and we got them to vote on the most important pain points.

The highest priority pain points for Santa’s Workshop were:

No Standard Request Format (4 votes)

Without a standard letter format and reliably easy-to-understand handwriting, a huge amount of time and resources are dedicated to manually creating request forms for every letter.

Manually Converting Requests to Work Orders (4 votes)

Every completed request form has to be manually converted into accompanying work orders to be distributed among the different toy production departments.

Manual Naughty/Nice Crossreferncing (3 votes)

Having to manually check each incoming request with the single copy of Santa’s naughty or nice list is a huge blocker in the process.

Inflexible Distribution (3 votes)

Once the distribution plan’s been handed to Santa, that’s it for the evening. There’s no way to update the schedule or respond to changes in conditions.

The Last Mile (2 votes)

As the least efficient part of the delivery process, the last mile makes up 28% of the limited resources Santa has at his disposal on Christmas Eve.

Improve Carbon Footprint (2 votes)

There’s increasing pressure from parents and shareholders to prove progress being made towards a completely carbon-neutral process.

The Solution

We took all this and put it to our in-house team of expert app developers.

To get a full range of different ideas and potential solutions for Mr Claus and co, we split everyone up into smaller groups. Each had a mix of product designers, developers, PMs, QA managers and account directors.

What did our team come up with?

You’ll have to wait until Part 2 to find out.